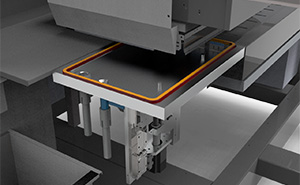

Industrial print heads, coupled with optimized ink arrangement, precise ink drop control, automatic detection of printing patterns, automatic fabric control and other functions, greatly improves printing accuracy and effect.

Industrial print heads, coupled with optimized ink arrangement, precise ink drop control, automatic detection of printing patterns, automatic fabric control and other functions, greatly improves printing accuracy and effect.

| High production capacity | High-precision | High-accuracy |

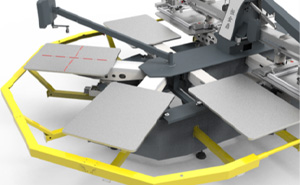

| “Oval + digital” technology is effectively combined. It avoids screen making and registration, and reduces the cost of multi-color printing. Production capacity can reach 450 pieces/hour (4pass, 30cm width) |

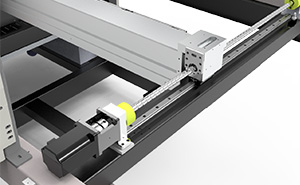

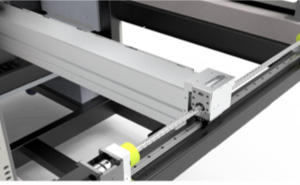

The X-axis uses a magnetic levitation linear motor, original THK silent linear guide rail from Japan, and metal grating positioning, with a horizontal printing accuracy of up to 0.01mm | The Y-axis uses Fuji high-precision servo motor and high-precision ball screw from Japan, ensuring accurate output of the absolute position of the printed image in the vertical direction and repeated positioning deviation ≤ 0.01mm |

|

|

|

| Long-life | Good effect | Good operation |

| The main transmission components are all imported from Japan, ensuring printing accuracy while achieving lifelong maintenance free operation |

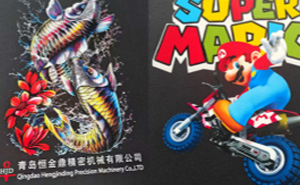

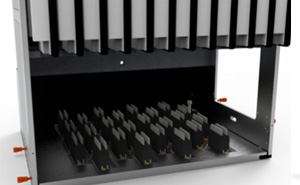

The color configuration scheme can reach up to 8 colors, with a full color gamut of light/spot colors available. A dual four-color symmetrical color scheme is introduced based on the characteristics of paint and ink, greatly improving production capacity and printing effect, and reducing color difference in reciprocating scanning | Hengjinding’s unique oval machine signal interaction system allows for sampling without the need for oval machine linkage, providing a wider range of operating modes, especially for multi head oval machines that are more convenient to use |

|

|

|

| Stable ink supply | Negative pressure stability | Long term moisturizing nozzle |

| Provide ink secondary filtration system, ink degassing system, and ink circulation recovery system to ensure that the ink entering the nozzle will not have any impurities or bubbles. Compared with similar models, it saves 2/3 of cleaning ink consumption and provides stable ink supply to ensure production | Using a standardized pneumatic negative pressure control system to accurately identify air leaks/under pressure/over pressure stability, ensuring that the pressure difference inside the air bottle is ≤ 0.1Kpa, compensating for constant pressure after temperature fluctuations, and ensuring uninterrupted production. At the same time, using gas/power off nozzle protection, no ink flow occurs during any shutdown | Full package large capacity nozzle moisturizing tray, long-lasting moisturizing nozzle, ensuring that the machine can be restarted at any time, with a maximum downtime of up to 15 days, allowing you to enjoy a long vacation with peace of mind; Leave enough space for customers to maintain and wipe the nozzle mirror surface |

|

|

|

| Nozzle collision protection | Power on protection | Security Warning |

| The serrated anti-collision sensors on both sides of this spray car are designed for textile fabrics; When the nozzle is detected rubbing against the fabric, the spray car will automatically raise and resume printing after the fabric surface is sorted | Pre filter each output power supply to adapt to the power supply environment of users in different scenarios and avoid interference from input circuit fluctuations on device output | X. Y and Z travel protection, private server motor overload alarm, ink shortage alarm, printing fault alarm, shutdown, etc., ensure absolute safety for users during use |

|

|

|

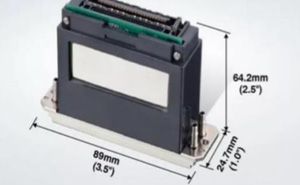

| Optional heads Ricoh G5/G6 | 4-color models (10 /12/16 heads), 6-color model (15 heads), 8-color model (16 heads, 24 heads) |

|

|

| Computer+monitor | Large printing area of 1000 * 1000mm |

|

|

| Motion unit linear guide rail | THK (Japan) |

| Y-axis grinding ball screw | TBI |

| Motherboard, spray car board, and nozzle driver board |

Royal |

BYHX |

|

| X-axis servo drive | Servotronix(Israel) |

| X-axis magnetic levitation linear motor | Smart win |

| Y-axis servo system | Fuji Electric(Lapan) |

| Switch power supply | Mean well(Taiwan) |

| Microswitch | Omron (Japan) |

| Photoelectric sensor | Omron (Japan) |

| Relay | Jarol |

| Spring terminal | UTL |

| Z-axis, moisturizing lifting and stepping system | Spark |

| Scratching step system | Leadshine |

| Circuit breakers and contactors | Chnt |

| Magnetic grid reading head | SIKO (Germany) |

| Pneumatic components | SMC (Japan) |

| Nozzle connection component | CPC(USA) |

| Pneumatic control valve | Airtac |

| Ink filter element | Cobetter |

| Ink degassing element | PALL(USA) |

| Print head | Ricoh(Japan) |

Star Fire (USA) |

|

| Ink supply pump | Jihpump |

| Ventilation solenoid valve | TPC(Republic of Korea) |

| RIP software | Neostampa (Spain) |

Maintop |