1. Full Servo Motor Drive: Core Power Guarantee for Stability and Precision

The I3200-A1*4 elliptical digital printer is equipped with a full servo motor drive system, which fundamentally ensures the stability, high precision and long service life of the equipment. With its precise position control and speed regulation capabilities, the servo motor effectively avoids problems such as operation jitter and positioning deviation that may occur with traditional drive methods. During the printing process, the pattern registration error is extremely small, and the color reproduction remains consistent. At the same time, the low-wear characteristic of the servo motor greatly reduces equipment failure rates and lowers subsequent maintenance costs. Even under long-term high-intensity continuous operation, it can still maintain stable performance output, providing reliable support for large-scale production.

2. Electric Nozzle Lifting: Flexible Adaptation to Diverse Media

The equipment innovatively adopts an electric nozzle lifting design. Users can directly set the current printing height through software without manually adjusting the mechanical structure, making the operation process more convenient, the height control more precise, and the printing stability significantly improved. In addition, this design endows the equipment with an extremely wide range of media thickness adaptability. Whether it is thin fabrics, regular-thickness cut pieces, or special materials with a certain thickness, it can be easily handled without frequent equipment replacement or complex parameter adjustments, greatly enhancing production flexibility and adaptability.

3. Multi-Process Integration: One Machine Meets All Needs

The I3200-A1*4 elliptical digital printer breaks through to realize the integrated integration of screen printing and 3D high-definition digital printing. There is no need to configure additional equipment, and one machine can complete the printing needs of multiple processes. The thick texture of screen printing complements the high-definition delicacy of digital printing. It can not only meet the efficient needs of large-area solid-color printing but also achieve the precise presentation of complex patterns and gradient colors, enriching the process expression of printed products. Without inter-equipment transfer, it effectively reduces the time-consuming process connection and product loss.

4. Cost-Effective Configuration: The Optimal Choice for Low Cost and High Efficiency

In terms of cost control and efficiency improvement, the equipment shows strong competitiveness. Its unique design supports one main unit equipped with two digital printing units, which is equivalent to obtaining double printing capacity with an investment close to that of a single device, greatly reducing the equipment depreciation cost per unit product. At the same time, the dual-unit parallel operation mode can promote mass production efficiently without additional site and labor input, significantly improving production efficiency. It has become the most cost-effective solution for small-batch production and bulk order processing, helping enterprises gain a cost advantage in fierce competition.

5. Full-Scenario Adaptation: Conquering Special Printing Challenges

The equipment has strong scenario adaptation capabilities. It can not only be competent for conventional garment printing and cut piece printing but also accurately conquer the printing challenges of special concave-convex positions. For example, parts with convex or concave structures such as chest pockets, trouser pockets, and pocket edges of clothing. Traditional equipment is prone to problems such as missing prints and pattern deformation. However, relying on its precise positioning system and flexible nozzle adjustment function, the I3200-A1*4 can closely fit the curved surfaces of special parts to achieve uniform and clear printing effects. This frees printing from the limitation of flat surfaces and expands the design space and application scenarios of products.

6. Simplified Plate Making Process: An Efficient Tool for Small-Batch Production and Sampling

Addressing the pain points of small-batch production and sample making, the equipment greatly simplifies the plate making process, eliminating the need for complex plate-making procedures. Especially in the white plate production link, there is no need for tedious color separation processing, and the operation is simple and convenient. Whether it is small-batch orders of 50-300 pieces or urgent sample making needs, it can respond quickly to achieve same-day sampling and same-day large sample output for efficient delivery. This advantage not only reduces the labor cost and plate-making time of the plate room but also helps enterprises quickly meet customer needs, shorten the order confirmation cycle, and improve customer satisfaction. It has strong competitiveness in the small-batch customization and rapid sampling market.

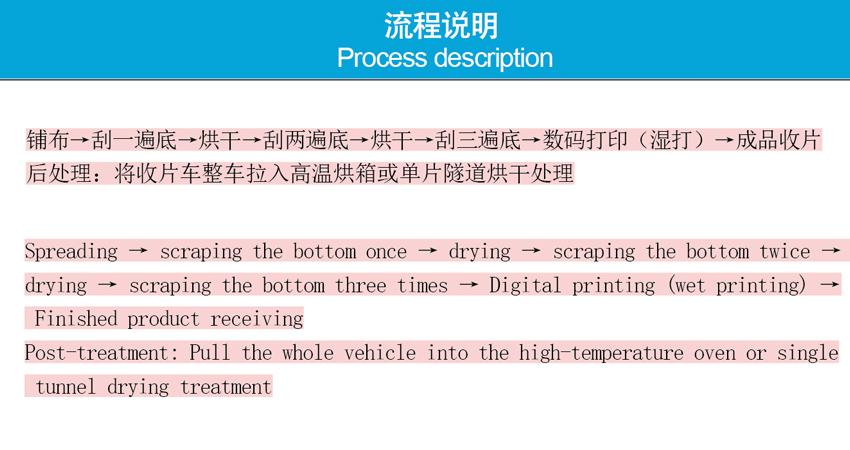

7. Multi-Material Compatibility: Creative Extension Integrating Traditional Crafts

The digital printing unit takes the printing machine as a stable printing platform, accurately matching the scraping position of the printing machine. It is compatible with various printing materials such as water-based paste, glue paste, ink, and thick plate paste, adapting to different printing effect requirements. At the same time, the equipment can also be deeply integrated with traditional crafts such as hot stamping, foaming, and electrostatic flocking. On the basis of digital printing, it superimposes rich process textures, making printed products not only bright in color and clear in pattern but also having diverse sensory experiences such as three-dimensional concavity and convexity, velvet touch, and metallic luster. The products have distinct differentiated characteristics, better meeting the market’s demand for high-quality and personalized printed products.