Scanning printing, high-precision industrial nozzle, variable ink dot functionSpeed 720㎡/h, Printing accuracy 1,200 DPI Suitable for cotton, linen, silk and other fabrics

Scanning printing, high-precision industrial nozzle, variable ink dot functionSpeed 720㎡/h, Printing accuracy 1,200 DPI Suitable for cotton, linen, silk and other fabrics

| High speed | More concise interaction |

| 1.5m/s high-speed scanning with maximum vehicle speed, 1pass printing up to 1100m/h printing speed |

Touch screen human-computer interaction makes using the machine more intuitive and concise, supports one-click switching between Chinese/English (other languages can be customized), and supports user functions to expand custom functions. |

|

|

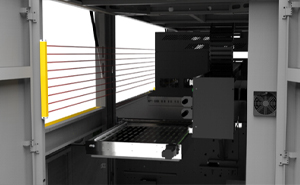

| Multiple protection for nozzles | More stable |

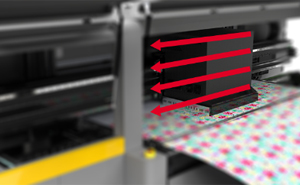

| This machine is equipped with forward cloth over- height warning, scanning over-height protection on both sides of the front of the machine, over-pull over -height nozzle protection at the cloth outlet, etc. After triggering, the spray car will automatically rise to the highest level to prevent the nozzles from contacting the printing cloth surface. |

The main beam uses steel-aluminum composite beams to ensure rail surface accuracy while greatly improving structural stability and continuously outputting high- precision printing. |

|

|

| Easy to clean | Emergency stop and continued printing |

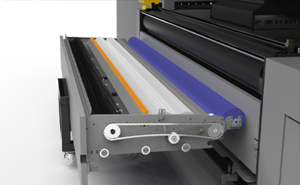

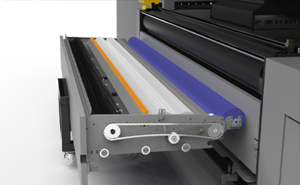

| After the brush roller roughly cleans the guide belt surface, add a scraper device to further clean the remaining cloth scraps on the guide belt. At the same time, add more water-absorbing rollers in front of the clothes to reduce the time and temperature required for the clothes and improve the cleaning of the guide belt. Efficiency makes belt cleaning easier |

When the fabric enters the printing area, if it detects that the fabric is too high, the trolley will quickly stop on the spot and raise the spray car to the highest point and then return to the original point to moisturize. After waiting for the abnormal fabric to be processed, you can continue to click on the software to continue printing, effectively |

|

|

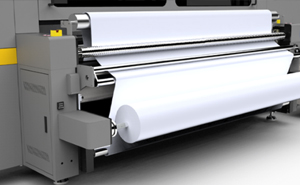

| Automatic shrink roll | Safer for operators |

| Unwinding with tension/tension-free cloth mode switching, fully automatic servo spreading system, effectively avoiding pressure bar marks, aluminum alloy opening: efficient flattening/wrinkle removal and stretching, universal collecting system for needle/ woven fabrics |

Add a light curtain at the front of the trolley to prevent the operator from looking into the equipment to observe the operation or printing effect, causing the equipment to stop running immediately and prevent unexpected situations |

|

|

| Main board, spray car board and print head driver board | Hosonsoft  |

| PLC, input and output modules and touch screen | Xinje  |

Inovance |

|

| PLC, input and output modules and touch screen | Servotronix(lsrael) |

| Y-axis, cloth spreading, cleaning and cloth placing servosystem | Xinje |

| Switching Power supply | Mean Well(Taiwan) |

| Proximity switches | Autonics (Korea) |

Fotex |

|

| Photoelectric Sensors | Omron |

| Height limit photoelectric sensor | Keyence (Japan) |

| Ultrasonic Sensors | Pepperl+Fuchs(Germany) |

| Light Curtain | Sensor Intelligence |

| Relay | Jarol (Switzerland) |

| Spring terminals | UTL |

| Z-axis, moisturizing lifting and stepping system | SP |

| Ink scraping stepping system | Leadshine |

| breaker | Chnt |

| guide | THK (Japan) |

| Conduction band | Habasit(Switzerland)  |

Highten |

|

| Reducer | Nyoshichi |

Highten |

|

| Linear Motors | DICI |

| Pneumatic components | SMC (Japan) |

| Printinghead connection assembly | CPC(USA) |

| Gas line control valve | Airtac (Taiwan) |

| Positive and negative pressure switching valve | Takasago (Japan) |

| Ink filter element | Cobetter |

| Ink degassing element | PALL (USA) |

| Printinghead | Kyocera (Japan) |

| Ink supply pump | Jihpump |

Linglu |

|

| Ventilation solenoid valve | TPC(South Korea) |

| Ink degassing element | Neostampa (Spain) |

| Magnetic grid and magnetic grid reading head | SIKO |

Conveyor Belt Printing Machine | Unleash Maximum Efficiency & Precision

Unlock unparalleled performance with our Conveyor Belt Printing Machine, expertly crafted to elevate your printing production. Built with the latest technology and designed for seamless operation, it guarantees exceptional speed, quality, and reliability—the perfect solution for businesses demanding high-efficiency, low-maintenance, and cost-effective printing.

Why Choose Our Conveyor Belt Printing Machine?

Magnetic Levitation Linear Motor (X-axis) – Smoother, Quieter, and Maintenance-Free

Enjoy effortless operation with our advanced magnetic levitation motor that guarantees zero maintenance for life, ensuring continuous high-performance without interruption.

Japanese DESBOER Precision Planetary Gear Reducer (Y-axis) – Silent, Stable, and Durable

Featuring ultra-precise stepper control, this system offers exceptional durability and whisper-quiet performance, making it the perfect solution for high-demand environments.

Integrated Cleaning & Moisturizing System – Saves Time, Reduces Downtime

The all-in-one cleaning and moisturizing system ensures that all nozzles are cleaned in a single pass, minimizing maintenance time and ensuring consistent print quality with long-lasting moisture.

Swiss RAPPLON Conveyor Belt – Precision & Durability for a Lifetime

Made from high-precision Swiss RAPPLON, our conveyor belt guarantees outstanding durability and long-term performance, ensuring smooth operation throughout its lifetime.

Ink Shortage Alarm – Never Run Out of Ink Mid-Print

Stay ahead of production delays with the ink shortage alarm, alerting you well before the ink runs out, so you can focus on production without interruptions.

Industrial-Grade Negative Pressure Ink Supply System – Consistent Quality in Any Environment

This advanced ink system ensures that high-speed printing is achievable even in challenging conditions, delivering consistent results with every print.

Quadruple Nozzle Protection System – Safeguard Your Equipment

Laser sensors for real-time cloth height monitoring

Anti-collision protection on both sides of the trolley

Ultra-high sensor at the cloth outlet to prevent over-pulling

Anti-overpull roller to protect the cloth and reduce wear

Flexible Printing Options – Adaptable to Various Processes

With a printing width range of 1.8 to 3.2 meters, this machine supports pigment, reactive, disperse, and acid ink printing, making it suitable for diverse production needs.

High-Speed, High-Volume Output – Maximize Your Efficiency

Choose between 4 or 8-color output and install 8, 12, 16, or 24 print heads, achieving speeds of up to 300 m²/h, making this machine perfect for large-scale, high-speed production.

Unlock the Full Potential of Your Printing Business!

With its advanced features, user-friendly design, and exceptional durability, our Conveyor Belt Printing Machine is the ideal choice for businesses looking to enhance production efficiency, reduce maintenance costs, and improve print quality.

Don’t settle for less. Upgrade to superior performance today and experience the future of printing.