Speed up to 30 ㎡/hour The best choice for custom orders: easy to use, no need for pattern making, good printing effect, high precision and high efficiency.

Speed up to 30 ㎡/hour The best choice for custom orders: easy to use, no need for pattern making, good printing effect, high precision and high efficiency.

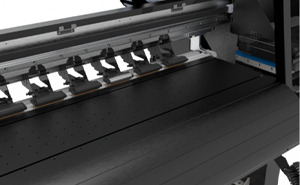

| High precision | Stable structure and long-lasting accuracy |

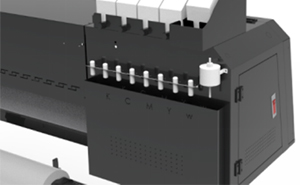

Ink stack automatic lifting, cleaning and moisturizing system |

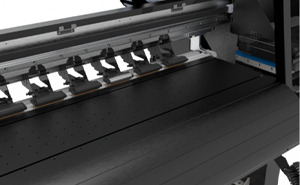

| X-axis aluminum alloy precision machined crossbeam+Yadeke high-precision silent guide rail, matched with Leisai integrated stepper motor control, white color matching accurate to within 2 threads |

The high-strength die opening thickened aluminum alloy base is firmly combined with the machine head, with a precision machining flatness of ≤ 0.03. It is matched with a full aluminum alloy suction platform group to provide l ong-lasting high-speed and high-precision printing |

The nozzle adopts a maintenance free integrated lifting ink stack for moisturizing, which is durable and long-lasting safe nozzle protection |

|

|

|

| Missing film alarm | White ink circulation+ stirring+shaking ink |

Nozzle protection and maintenance |

| Configure film shortage alarm shutdown. When the film is exhausted, the electronic sensor detects a paper shortage status, the software alarms and stops printing to prevent empty printing and nozzle rubbing. The printer can achieve unmanned operation |

White ink circulation and stirring system, Hengjinding’s unique independent shaking function of white ink pot, fully shaking without dead corners, preventing white ink sedimentation and ensuring smooth production |

The spray car is equipped with collision protection systems on both sides of the nozzle, which can quickly stop in case of accidental impact or scratching of the printing film; Manually pressing the ink suction device makes it easier to maintain the ink pad |

|

|

|

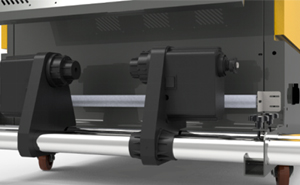

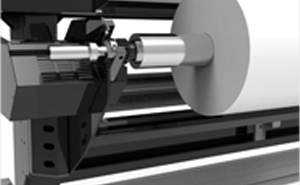

| Constant tension automatic film release system |

Wear resistant pressure wheel structure |

Ink shortage alarm |

| Dual power automatic unwinding with constant tension film feeding structure, stable high-speed printing and film feeding, ensuring the accuracy of step-by-step paper feeding; Support 300 meter large roll printing film, batch production without frequent roll changes, more convenient to use |

The Y-axis drive uses imported fluororubber large paper pressing wheel, which does not generate static electricity. It does not need to adjust the step again to change the film at will, so as to ensure that the single facial mask moves stably without slipping and does not damage the printing surface of the hot stamping film |

Ink cartridge level alarm system, when the main ink cartridge is low on ink, the buzzer will sound and the corresponding indicator light will light up, prompting the user to add ink |

|

|

|

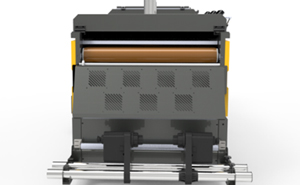

| Three zones independent temperature control+Teflon conveyor belt |

Cool down quickly | Dual power paper delivery system |

| Double-sided heating of the guide plate + three-zone independent temperature control. Extra longer heating area to achieve better results and prevent oil and water backflow |

Drying outlet dual row cold air cooling, rapid cooling before winding |

Use a dual power paper feeder to meet the needs of larger paper rolls; At the same time, adding a tension adjustment rod before winding can avoid deviation while making the large roll more compact |

|

|

|

|

|

|

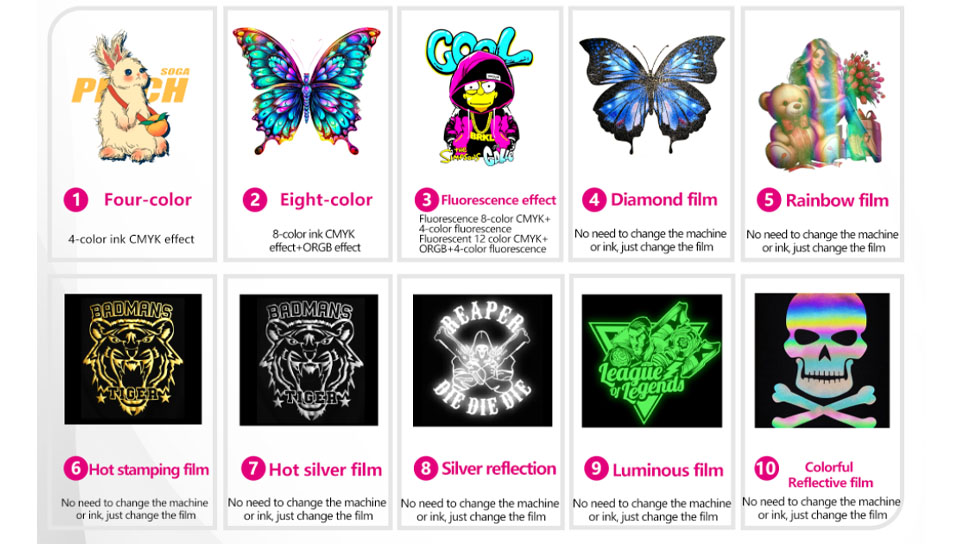

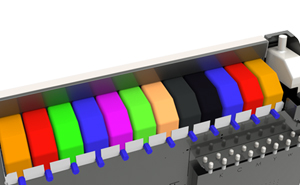

| Optional 8 or 12 colors | Support mainstream RIP software in the market |

Air shaft unwinding (film length>300 meters) |

List of Accessories Brand Configuration

| Motion unit linear guide rail | Airtac (Taiwan) |

| Bearing | Bearing |

| Stepping motor | Leadshine |

Just motion cintrol |

|

| Photoelectric sensor | LG |

| Switch power supply | Jiannuo |

| Board card | Hosonsoft |

| Button Switch | HBAN |

| Relay | Carlo Gavazzi |

| Spring terminal | UTL |

| Pneumatic components | SMC (Japan) |

| Circuit breakers and contactors | CHNT |

| Printhead connection component | CPC (USA) |

| Pneumatic control valve | Airtac (Taiwan) |

| Positive and negative pressure switching valve | Gaosha (Janpan) |

| Ink filter element | Cobetter |

| Ink degassing element | PALL (USA) |

| Printhead | EPSoN |

| Ink supply pump | Jihpump |

| Ventilation solenoid valve | TPC (Korea) |

| RIP software | Maintop |