Epson i3200-A1*2 Printer parameters

| Device type | 2-head printer | Printhead Model | Epson i3200-A1*2 |

| Max print width | 65cm | Working environment | Temperature:20°C-28°C; Humidity:65-75% |

| Print accuracy | 720dpi1800dpi 6 pass;720dpi2400dpi 8pass | Working power supply | 220V;50HZ/60HZ 3.5A |

| Printing software | Hosonsoft | Outside dimensions | 18007801700mm LWH |

| RIP software | MainTop | Packing size | 1950920960mm LWH |

| Sprinkler maintenance | Automatic cleaning, automatic moisturizing | The weight of | 170kg; Packing weight:210kg |

| Print speed | 6pass 8-15m²/h;8pass 5-12m²/h | Power | 750w |

| Ink type and configuration | Pigment ink; C、M、Y、K、W | Optional configuration | cadlink /photoprint /printfactory (XBYX) |

| Consumables usage | White ink: 25ml/square meter;Color ink: 12ml/square meter;Hot melt powder: 30g/square meter | ||

Standard Powder Drying Machine Parameters

| Device type | Standard Powder Drying Machine | Match the model | 2 Printhead printer |

| Number of lamps | 5 pcs | Working power supply | AC220V/50Hz 20A |

| Power | 4200W | Packed in wooden case size | 183010801250mm |

| Outside dimensions | 248010501090mm | weight | 220kg Net weight 220kg; 280kg Package weight 280kg |

|

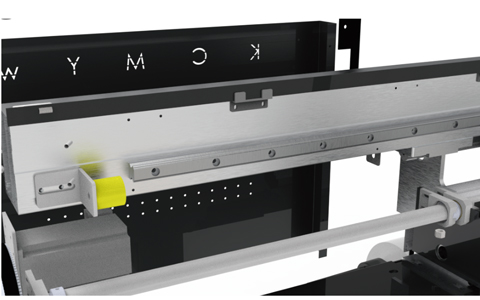

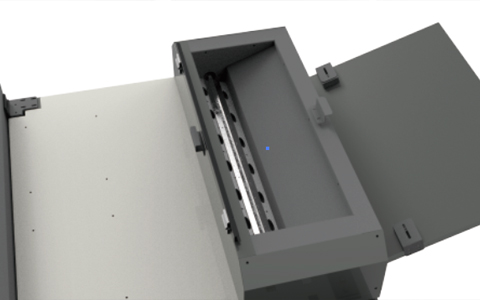

1. Xaxis aluminum alloy precision machined crossbeamtYadeke high precision silent guide rail, controlled by a LeiSai integrated stepper motoland the white color matchingis precise to within 2 threads |

|

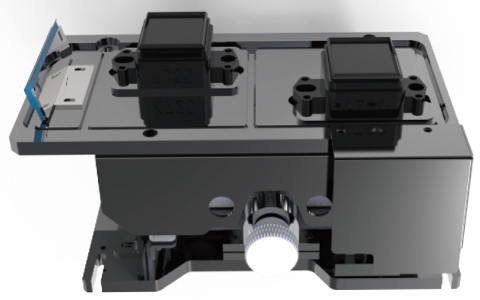

2. The highstrength die opening thickened aluminum alloybase is Xrmly combined with the machine head, with aprecision machining Xatness of < 0.03. It is matched withan all aluminum alloy suction platform group to providelong-lasting high speed and high precision printing |

|

3. The nozzle moisturizing adopts a maintenancefree integrated lifting ink stack, which is durableand protects the nozzle safety |

|

Congure lm shortage alarm shutdown. When the lm4.is exhausted, the electronic sensor detects a papershortage status, the software alarms and stops printingtoprevent empty printing and nozzle rubbing. The printercan achieve unmanned operatione rubbing, printer canachieve unmanned operation |

|

5. Ink cartridge level alarm system, when themain ink cartridge is low on ink, the buzzer willsound and the corresponding indicator light willlight up, prompting the user to add ink |

|

6. White ink circulation and stirring system,Hengjinding’s unique independent shakingfunction of white ink pot, fully shaking withoutdead corners,preventing white ink sedimentationand ensuring smooth production |

|

7. The sprav car is eauipped with collisionprotection svstems on both sides of the nozzle,which can uickly stop in case of accidentalimpact or scratching of the printing lm:Manually pressing the ink suction device makes iteasier to maintain the ink pad |

|

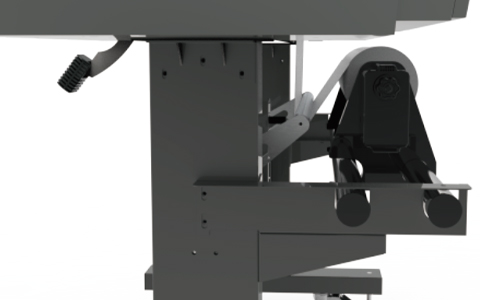

8. Dual power automatic unwinding withconstant expansion force lm feeding structure,stable highspeed printing and lm feeding.the accuracy of step-by-stepensurilngpaperfeeding:Support 300 meter large rollprintingIm, batch production does not require frequentroll changes, making it more convenient to use |

|

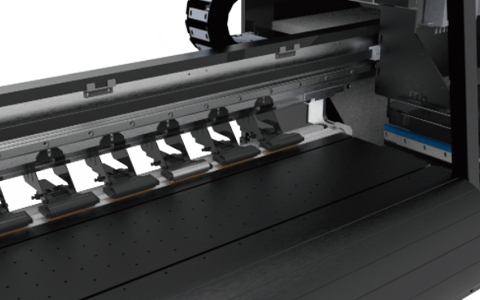

9. The Yaxis drive uses imported uororubberlarge paper pressing wheel. which does notgenerate static electricity. It does not need toadiust the step again to change the lm at will.so as to ensure that the single facial mask movesstably without slipping and does not damage theprinting surface of the hot stampingl m |

|

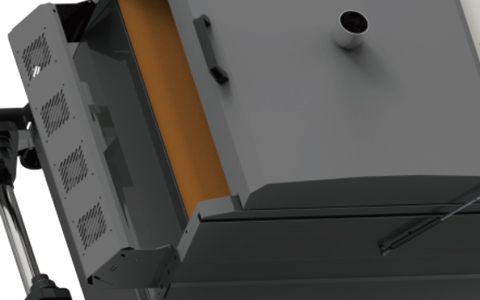

1. The standard intelligent temperature controlis precise, with mesh belt speed regulation andadjustable powder feeding amount |

|

2. Mesh belt suction lm for easy sampling |

|

3. Increase the powder box without frequentpowder addition |

|

4. Automatic winding+front cold air |