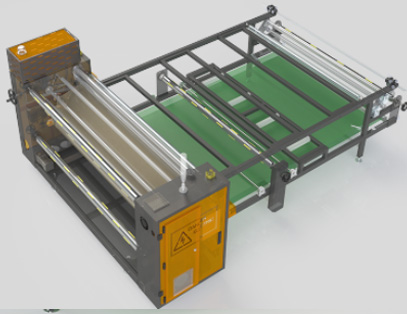

The roller printing machine is suitable for sublimation transfer of large banners, flags, non-woven fabrics, clothing fabrics and other products.

The roller printing machine is suitable for sublimation transfer of large banners, flags, non-woven fabrics, clothing fabrics and other products.

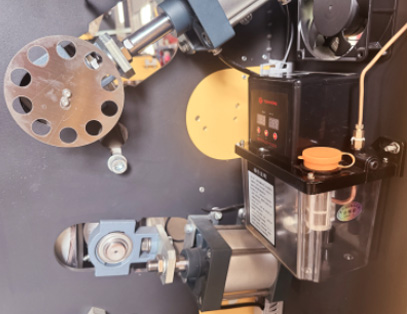

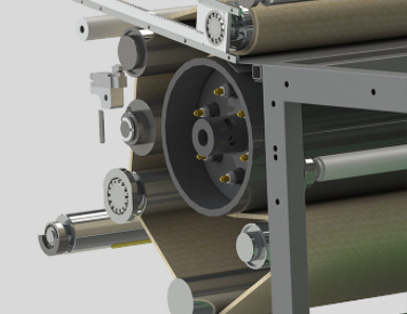

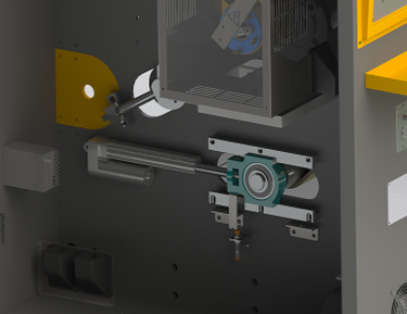

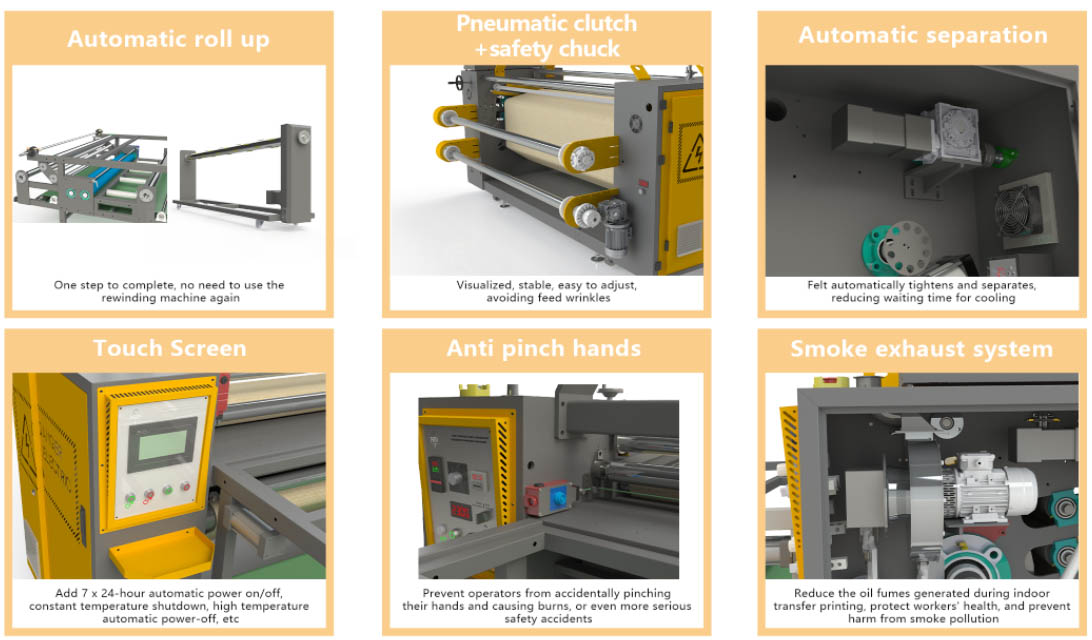

| Automatic oiler, avoiding manual operation errors and extending service life |

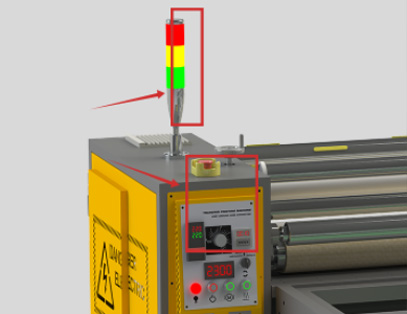

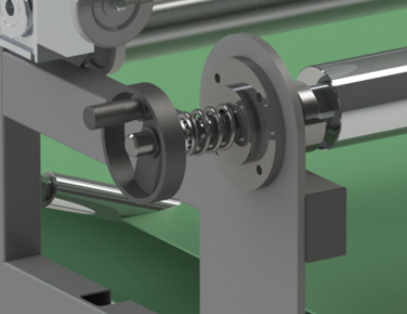

Felt abnormal operation detection | Felt wrapping area reaches 75% to save power consumption. |

|

|

|

| LLD display, timed shutdown, abnormal shutdown and over-temperature sound and light alarm |

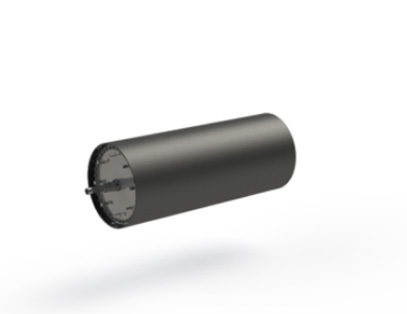

Standard 100% nomax felt with quality assurance, long life and good effect |

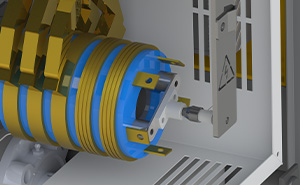

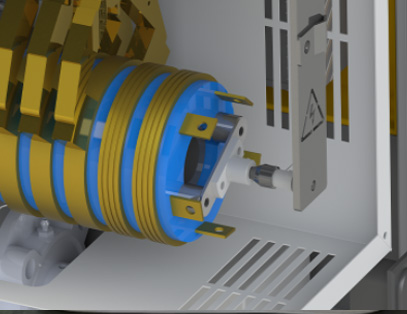

Standard mercury slip ring for precise temperature control |

|

|

|

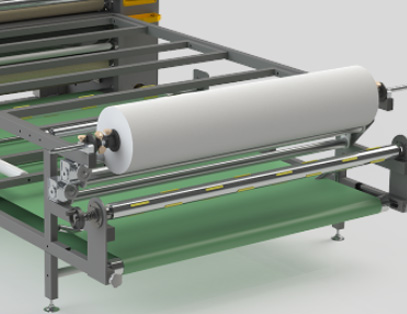

| Fabric roll with positioning to prevent deviation, no need formanual labor adjust |

With 4 air shafts for lining paperdrawing paper rewinding and unwinding. which is easy to operate and reduces defective rate |

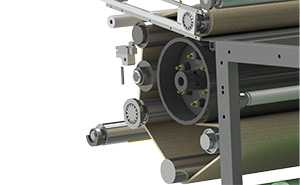

Felt automatic correction function No need for manual adjustment |

|

|

|

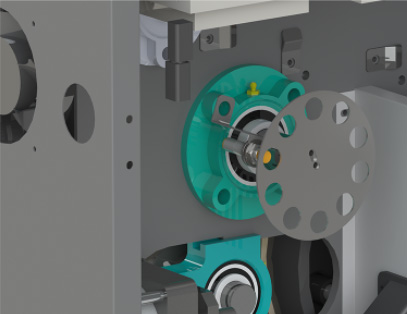

| Special structure of heating roller Ensure a temperature difference of ± 1.5 ℃ between the left, middle, and right sides to avoid color deviation |

Automatic correction of conveyor belt | Shutdown and automatic power-off |

|

|

|

| frequency converter | ADT |

| PLC | Xinjie |

| temperature control | Omron |

| Air source control | Airtac |

| Mounted Bearings | TR |

FSB |

|

| Circuit breaker | Chnt |

| Correction induction | Omron |