A3 Film Making Machine Parameters

|

Device type |

A3 printer |

Printhead Model |

Epson7610/2、XP600*2 |

|---|---|---|---|

|

Max print width |

33cm |

Working environment

|

Temperature:20°C-28°C

Humidity:65-75%

|

|

Print accuracy |

XP600:360dpi*1080dpi 6 pass

XP600:360dpi*1440dpi 8 pass 7610:720dpi*1800dpi 6 pass 7610:720dpi*2400dpi 8 pass |

Working power supply |

220V

50HZ/60HZ 3A |

|

Printing software

|

BetterPrinter/Hosonsoft

|

Outside dimensions

|

12006501150mm

LWH

|

|

RIP software

|

MainTop

|

Packing size

|

13246741388mm

LWH

|

|

Sprinkler maintenance

|

Automatic cleaning,

automatic moisturizing

|

The weight of

|

134kg 184kg |

|

Print speed

|

6pass 3-4m²/h

8pass 2-3m²/h

|

Power

|

500w |

|

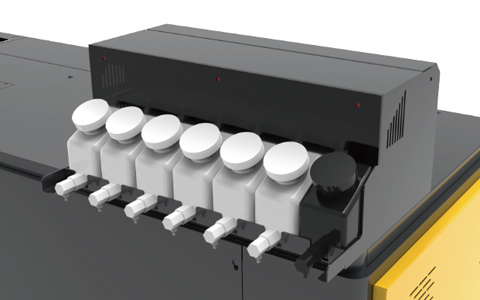

Ink type and configuration

|

Pigment ink

C、M、Y、K、Lc、Lm、W

|

Consumables usage |

White ink: 25ml/square meter Color ink: 12ml/square meter

Hot melt powder: 30g/square meter |

|

Device features

|

Small footprint, low use and maintenance costs, affordable nozzle price

|

||

A3 Powder Drying Machine Parameters

|

Device type |

A3 powder dryer |

Match the model |

A3 printer |

|---|---|---|---|

|

Number of lamps

|

3 pcs |

Working power supply

|

AC220V/50Hz 5A |

|

Power

|

1000W |

Packed in wooden case size

|

1120740780mm |

|

Outside dimensions

|

1020625625mm |

weight

|

Net weight 53kg

Package weight 88kg

|

|

Device features

|

1. Small footprint, flexible handling 2. Easy to learn and save labor 3. Precise temperature control

|

||

|

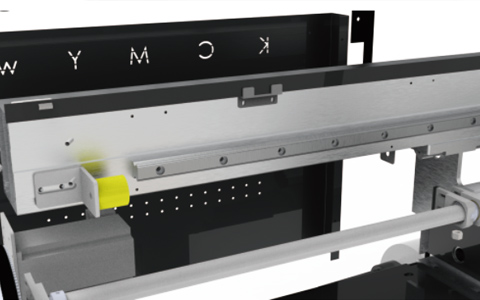

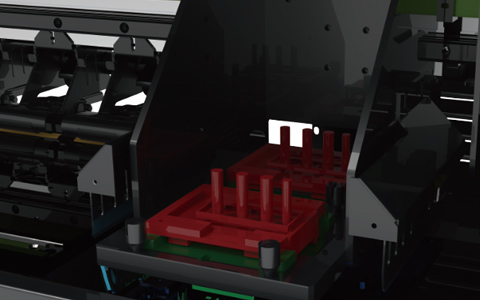

1.Xaxis aluminum alloy precision machinedcrossbeam+Yadeke high-precision silent guiderail |

|

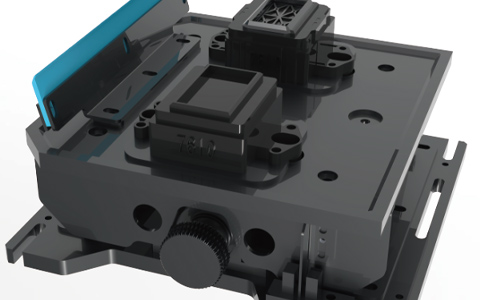

2. The entire machine is controlled by a Lei Saiintegrated stepper motor, and the white colormatching is precise to within 2threads |

|

3. The nozzle moisturizing adopts a maintenancefree integrated lifting ink stack, which is durableand protects the nozzle safety |

|

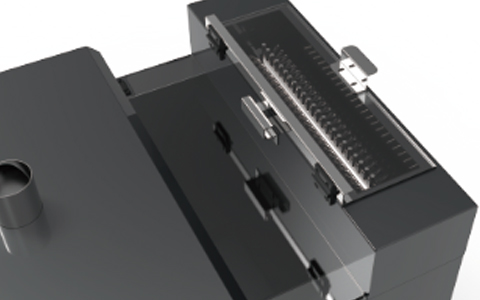

4. Congure lm shortage alarm shutdown. When the 1m is exhausted, the electronic sensor detects a papershortage status, the software alarms and stops printing toprevent empty printing and nozzle rubbing. The printercan achieve unmanned operatione rubbing, printer canachieve unmanned operation |

|

5. Equipped with a white ink circulation andstirring system:Ink cartridge level alarm system,when the main inkcartridge is lowon ink,thebuzzer sounds and the corresponding indicatorlight lights up, prompting the user to add inkandensuring smooth production |

|

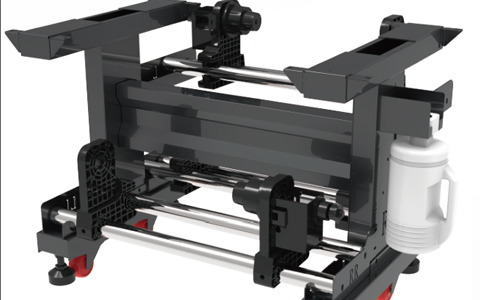

6. The spray car is equipped with anti-collisionprotection systems on both sides of the nozzle,which can quickly stop in case of accidental impactor scratching of the printing lm. The lm outletextends outward, and it will not aect the digitalprinting when the powder dispenser is abnormal |

|

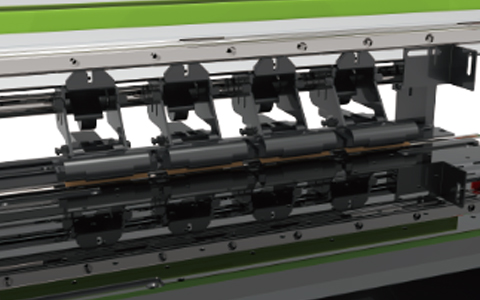

7. The Y axis drive uses imported uororubberlarge paper pressing wheel, which does notgenerate static electricity. It does not need toadjust the step again to change the lm at will,so as to ensure that the single facial mask movesstably without slipping and does not damage theprinting surface of the hot stamping lm |

|

1. Intelligent temperature control is precise,and the amount of powder can be adjustedarbitrarily |

|

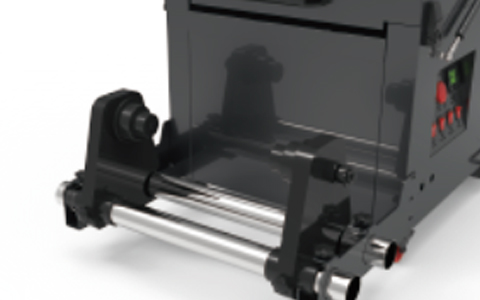

2. Increase thepowder addition powder box without frequent |

|

3. Dual power paper feeder for tighterwindingwithout deviatior |