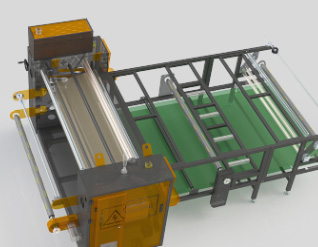

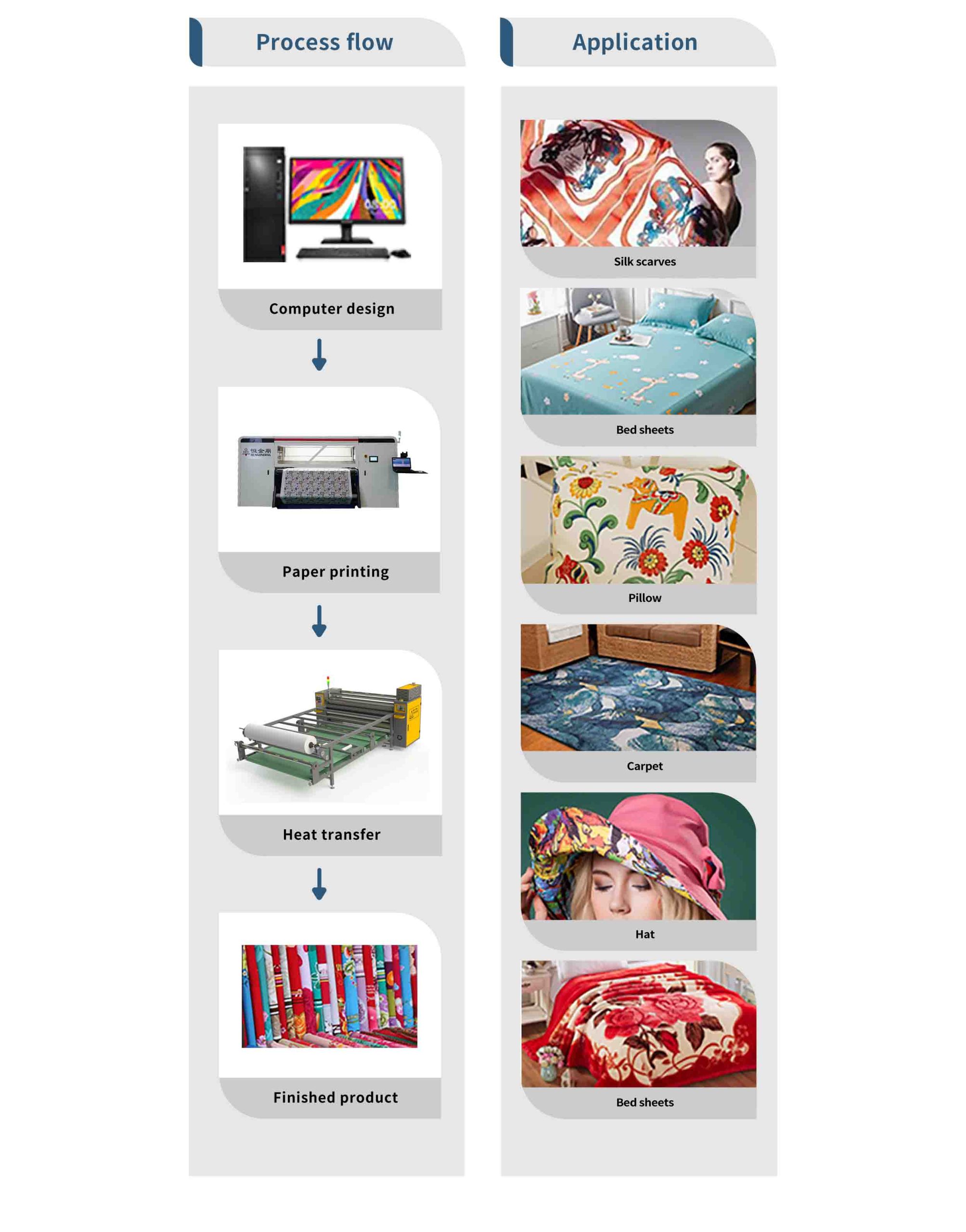

The roller printing machine is suitable for sublimation transfer of large banners, flags, non-woven fabrics, clothing fabrics and other products.

The roller printing machine is suitable for sublimation transfer of large banners, flags, non-woven fabrics, clothing fabrics and other products.

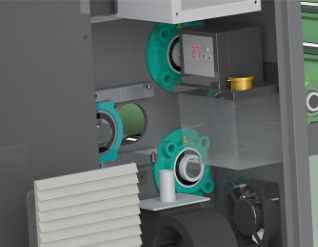

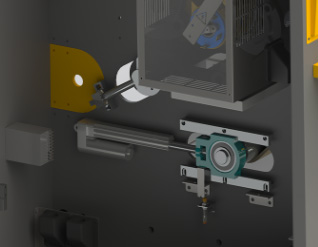

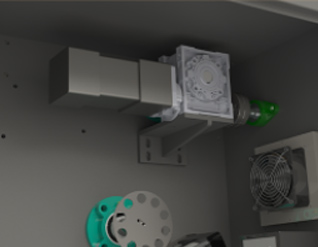

| Automatic oiler, avoiding manual operation errors and extending service life |

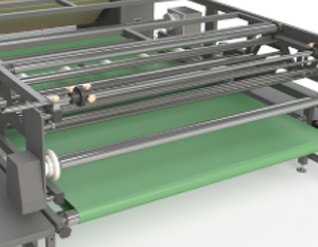

Felt abnormal operation detection | Felt wrapping area reaches 75% to save power consumption. |

|

|

|

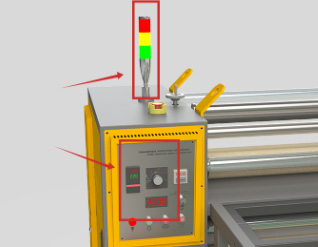

| LLD display, timed shutdown, abnormal shutdown and over-temperature sound and light alarm |

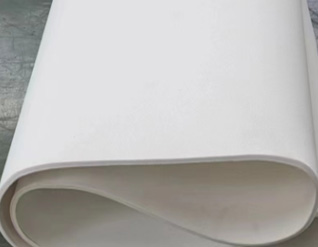

Standard 100% nomax felt with quality assurance, long life and good effect |

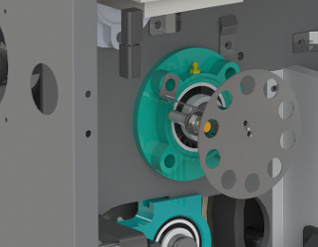

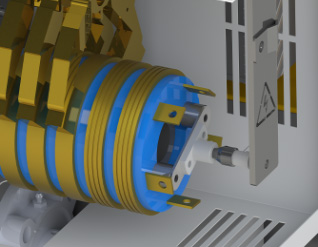

Standard mercury slip ring for precise temperature control |

|

|

|

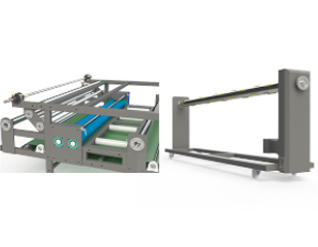

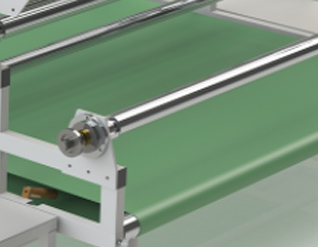

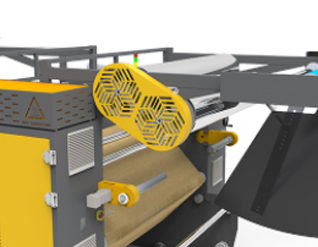

| Fabric roll with positioning to prevent deviation, no need formanual labor adjust |

Equipped with 3 aluminum inflation shafts, both protective paper and drawing paper use inflation shafts,Easy for customers to operate |

Felt automatic correction function No need for manual adjustment |

|

|

|

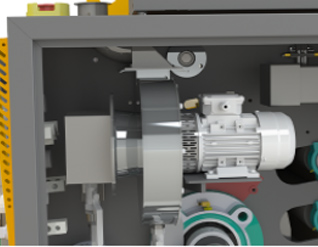

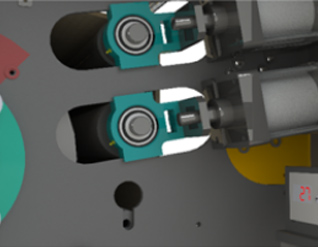

| Special structure of heating roller Ensure a temperature difference of ± 1.5 ℃ between the left, middle, and right sides to avoid color deviation |

Automatic correction of conveyor belt | Transparent dust cover for easy observation of slip ring operation status |

|

|

|

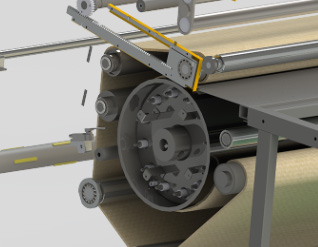

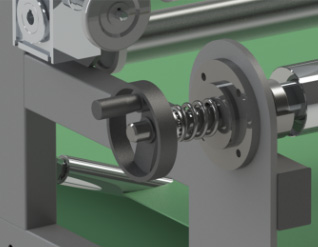

| Automatic roll up | Pneumatic clutch +safety chuck |

Automatic separation |

| One step to complete, no need to use the rewinding machine again |

Visualized, stable, easy to adjust, avoiding feed wrinkles |

Felt automatically tightens and separates, reducing waiting time for cooling |

|

|

|

| Touch Screen | Anti pinch hands | Smoke exhaust system |

| Add 7 x 24-hour automatic power on/off, constant temperature shutdown, high temperature automatic power-off, etc |

Prevent operators from accidentally pinching their hands and causing burns, or even more serious safety accidents |

Reduce the oil fumes generated during indoor transfer printing, protect workers’ health, and prevent harm from smoke pollution |

|

|

|

| Cloth pocket groove | Double release paper inflation axis |

WiFi function |

| The fabric does not need to be threaded and can be placed in the sliding groove |

Replacing the paper roll does not require cutting the material short, making it convenient and waste free |

After connecting to the WiFi function, remote control can be achieved using a mobile phone |

|

|

|

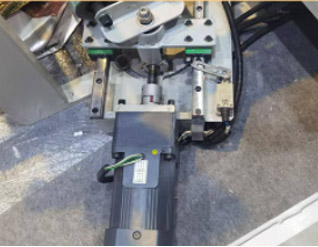

| Silicone pressure roller | High and low power switching | Independent electrical box |

| Silicone pressure roller improves transfer printing effect |

High and low power switching is more widely applicable in power environments |

Independent electrical box and host insulation extend the lifespan of electrical components |

|

|

|

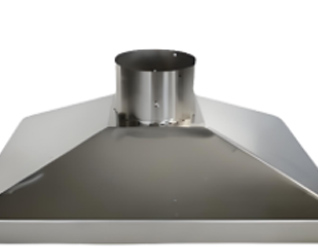

| exhaust fume collecting hood | Fabric water cooling | Feeding correction |

| Collect transfer printing oil fumes, centrally eliminate them, improve air quality, centrally process them, and promote green environmental protection |

Thick/special fabric, fast cooling, preventing deformation and pollution |

The feed is centered for easy collection |

|

|

|

| frequency converter |  |

| PLC |  |

| temperature control |  |

| Air source control |  |

| Mounted Bearings |  |

| Circuit breaker |  |

| Correction induction |  |